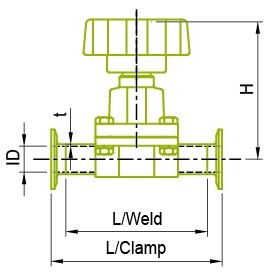

Diaphragm valve

Diaphragm valve

EFT

has developed a line of valve bodies that help address the needs of the Bioprocessing and Pharmaceutical industries for high quality, welded process systems.

By providing valve bodies with controlled sulfur SS316L stainless steel material and weld tangents long enough to accept the most common orbital weld heads in the industry, we have eliminated two of the most common concerns in valve-to-tube welding known today.

Automatic welding of 316L process components is greatly affected by the sulfur content of the mating process components. A disparity of sulfur content can result in reduced orbital weld quality and potentially incomplete fusion of the mating components. By controlling valve body sulfur content to the same chemistry as that required for ASME BPE fittings, welding problems due to material chemistry differences will be greatly reduced.

The EFT

of valve bodies fully complies with the controlled sulfur requirements for chemical composition of SS316L material, set by the ASME Bioprocessing Equipment Standard 2002. By increasing the valve weld end tangent lengths to the values required for ASME BPE fittings, we made the valve body compatible with virtually any orbital weld head utilized in the industry. Special offset or narrow heads are no longer required to weld a valve into a process system.

Hot Products

Hot

Hot

Vacuum Components

Hot

Hot

Vacuum Components

EFT provide flanges not only KF, ISO but also CF standard specification . We have...

Read More Hot

Hot

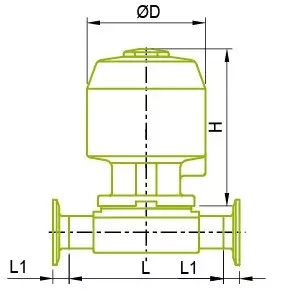

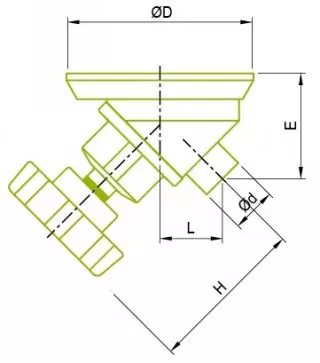

Sanitary Valve

Hot

Hot

Sanitary Valve

EFT can offer variety sanitary valve with food grade and get 3A certificate . Our diaphragm...

Read More Hot

Hot

Sanitary Fittings

Hot

Hot

Sanitary Fittings

EFT owns forging factory with the objective of building a professional image and providing...

Read More Hot

Hot

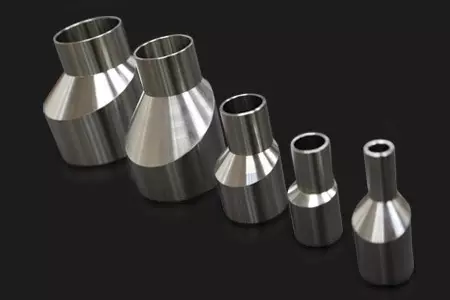

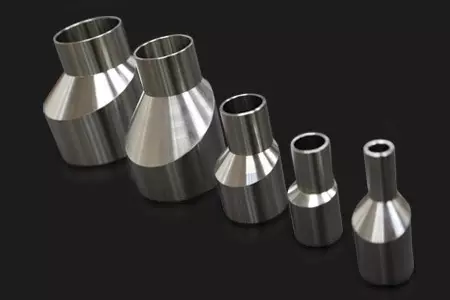

BPE Reducer

Hot

Hot

BPE Reducer

EFT can help with general issues or individual needs. EFT offers unique raw material...

Read More