Sanitary Tube

Specification

| Nominal Size | Tube Wall Thickness | Part Number | ||

|---|---|---|---|---|

| inch | mm. | inch | mm. | |

| 1/2 | 12.70 | 0.065 | 1.65 | 2401B003 |

| 3/4 | 19.05 | 0.065 | 1.65 | 2401B004 |

| 1 | 25.40 | 0.065 | 1.65 | 2401B005 |

| 1 1/2 | 38.10 | 0.065 | 1.65 | 2401B006 |

| 2 | 50.80 | 0.065 | 1.65 | 2401B007 |

| 2 1/2 | 63.50 | 0.065 | 1.65 | 2401B008 |

| 3 | 76.20 | 0.065 | 1.65 | 2401B009 |

| 4 | 101.60 | 0.083 | 2.11 | 2401B010 |

| 6 | 152.40 | 0.109 | 2.77 | 2401B011 |

| 8 | 203.20 | 0.120 | 3.05 | 2401B012 |

| 10 | 254.00 | 0.109 | 2.77 | 2401B013 |

All sizes of clamp end also available

ASME BPE PRODUCT SPECIFICATION

Material

316L, chemical composition in accordance with Table DT-3

304L, 1.4404 and 1.4435 also available

Tolerances

According to ASME BPE-2009 Table DT-5 and Table DT-6

Weld Ends

Weld ends of tubes and fittings are prepared for orbital automatic tube weld

Surface Finish

We provide quality mechanical polish from 32 µ-in through to 15 µ-in.

Electropolishing and other requirements are available upon request.

Test Procedures

Control of dimensions

End preparation

Internal surface roughness measurements

Visual inspection

Product Marking

Besides EVERFIT, we will imprint the part number, heat number,

ASME BPE and surface finish designation

Packaging

All finish products will be packed to suit the special conditions for

international deliveries.

Documentation

Certified material test report 3.1 as per DIN EN 10204/ASTM A1016.

Prematerial certification available upon request

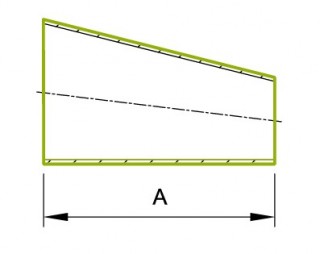

ORDERING INFORMATION : Surface Finish

Hot Products

Hot

Hot

Vacuum Components

Hot

Hot

Vacuum Components

EFT provide flanges not only KF, ISO but also CF standard specification . We have...

Read More Hot

Hot

Sanitary Valve

Hot

Hot

Sanitary Valve

EFT can offer variety sanitary valve with food grade and get 3A certificate . Our diaphragm...

Read More Hot

Hot

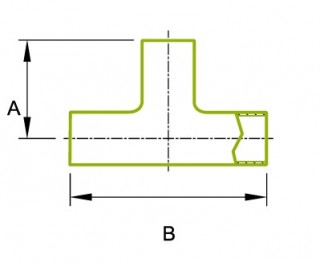

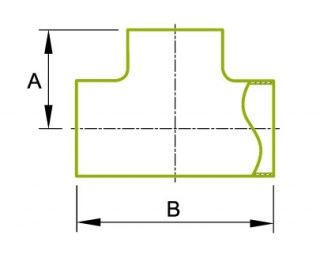

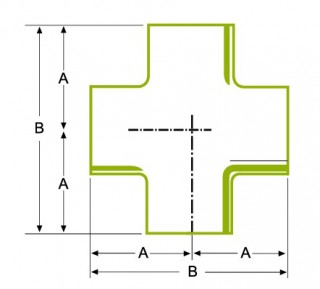

Sanitary Fittings

Hot

Hot

Sanitary Fittings

EFT owns forging factory with the objective of building a professional image and providing...

Read More Hot

Hot

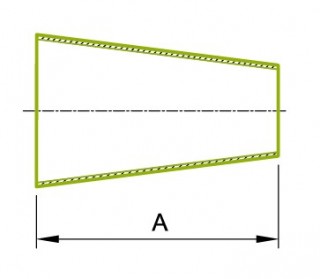

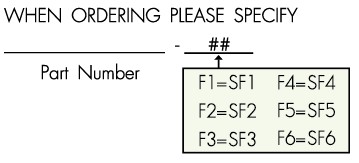

BPE Reducer

Hot

Hot

BPE Reducer

EFT can help with general issues or individual needs. EFT offers unique raw material...

Read More